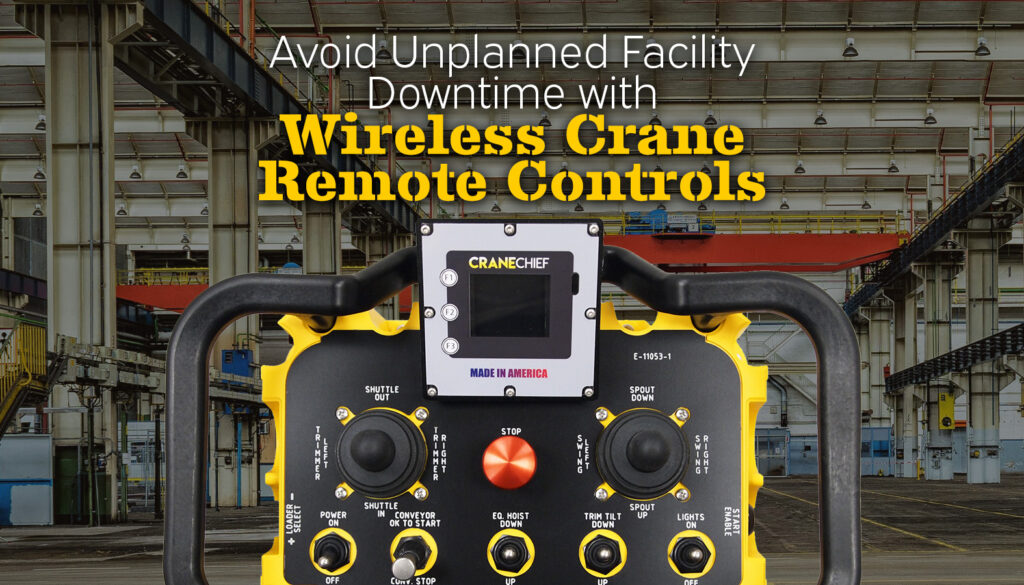

Avoid Unplanned Facility Downtime with Wireless Crane Remote Controls

Unplanned downtime is a killer – figuratively speaking. For industrial operations, it’s a terrible drain on productivity and profitability. You’re wise in scheduling facility downtime to handle routine maintenance for the tools and machines that get the job done. But you also hope to avoid unplanned facility downtime caused by emergency equipment breakdowns.

Wireless crane remote controls remove many variables that can cause such breakdowns, at least when it comes to your facility’s overhead material handling equipment. For many industries, that capacity is critical to the safe and efficient movement of dangerously heavy loads.

Don’t leave any of that to chance. Investing in wireless transmitter systems for cranes can improve your ROI by avoiding the dramatic costs of unplanned downtime. In this blog, we’ll underscore the critical importance of maintaining continuous facility operations and minimizing unexpected interruptions.

The Hidden Costs of Unplanned Downtime for Industries

Unplanned downtime is not just an inconvenience. It’s a substantial financial burden. According to recent studies, the average manufacturer faces around 800 hours of equipment downtime annually. (That’s over 15 hours each week.) The financial implications are staggering. Some industries lose thousands of dollars per minute when production unexpectedly skids to a halt.

Beyond the immediate costs of idle labor, wasted materials and reduced capacity, discerning business leaders like you must consider additional hidden costs:

- Labor Overhead: Idle operators and indirect labor costs accumulate quickly when you fail to avoid unplanned downtime.

- Production Delays: Unplanned downtime disrupts schedules, leading to missed deadlines and reduced output.

- Lost Revenue: Stopping production means tighter profit margins and potential penalties from unmet customer orders.

Improving Maintenance Efficiency to Avoid Unplanned Downtime at Your Industrial Facility

There’s a common sense solution, one that you likely embrace as basic math. One of the primary contributors to unexpected downtime is an inefficient maintenance process. Time spent due to unplanned maintenance is time lost. It’s crucial to improve maintenance efficiency to limit that downtime as much as possible.

In addition to improving facility efficiency while in operation, wireless crane remote controls simplify processes from your overhead crane’s installation all the way through planned upkeep.

Traditional reactive maintenance — fixing equipment only after it breaks — is outrageously expensive. We’d go so far as to say being reactive is completely ineffective. Here’s where we come in! Control Chief’s wireless remote controls and transmitters integrate seamlessly with predictive and preventative maintenance plans. They can also be custom designed to provide real-time data and control that can significantly reduce downtime incidents.

Wireless remotes solve problems before they happen. Here’s how:

1. Eliminating Downtime Caused by Wiring Issues

One of the most significant advantages of wireless crane remote controls – like our CraneChief™ Remote Control Transmitters – is the elimination of extensive wiring and conduits. Traditional wired systems require installation and ongoing maintenance of cables, which can be time-consuming and prone to issues such as wear and tear, environmental damage or accidental disconnection.

Wiring problems often lead to unexpected downtime for repairs. Wireless crane remote controls completely remove this risk.

2. Enhancing Safety

Imagine the horror of an accident on-site due to something entirely preventable. Physical obstacles and other hazards are common in many complex industrial environments. This could include a worker tripping over a crane wire or a multi-ton load crashing into something. These types of accidents could cause a workflow interruption – or worse, cause injury or death.

Wireless crane remote controls also contribute to a safer work environment by removing tripping hazards and other physical obstacles associated with wired systems. In an industrial setting, exposed wires and cables can become serious safety risks. By adopting wireless technology, these hazards are eliminated, creating a cleaner and safer workspace.

Additionally, in emergency situations, wireless remotes allow operators to promptly stop cranes, further reducing the risk of accidents that could lead to costly downtime.

3. Distancing & Mobility

Utilizing remote crane controls keeps operators at a safe distance from heavy machinery, reducing the risk of workplace mishaps and accidents that cause unplanned downtime. What’s more, operators aren’t confined to a specific location, allowing them to move freely and maintain optimal positions for visibility and control. This mobility is particularly beneficial in large facilities where multiple cranes are in use.

4. Optimized Workflow

The ability to control cranes from various points within a facility streamlines operations and eliminates bottlenecks. Operators can seamlessly transition between tasks, maintaining productivity and efficiency.

Reduced downtime directly translates to cost savings. By minimizing interruptions and maintaining continuous operations, wireless remote controls help companies avoid the high costs associated with equipment failure and idle time.

5. Data Collection

Wireless systems can be custom designed to collect and transmit data on equipment performance, usage patterns and maintenance needs. This data-driven approach allows for more informed decision-making and strategic planning. Better planning naturally equates to more uptime and productivity.

6. Versatility & Flexibility

Wireless crane remote controls are adaptable to various industrial environments and can be integrated with different types of cranes and hoists. This versatility ensures that companies like yours can customize their solutions to meet specific operational needs.

Avoiding unplanned downtime at your facility requires a special touch and the right tools for the job. Wireless technology can easily integrate with whatever overhead material handling technology you use.

Why Choose Control Chief for Wireless Crane Remote Systems?

Control Chief’s wireless crane remote controls are designed with the needs of industrial operations in mind. Our solutions offer:

- Robust Performance: Our wireless systems are built to withstand harsh industrial environments, ensuring reliable performance even in challenging conditions.

- Advanced Features: From extended range to real-time monitoring, our wireless crane remote controls come equipped with the latest technological advancements to enhance safety and efficiency.

- User-Friendly Design: Easy to install and operate, our systems require minimal training, allowing operators to quickly adapt and utilize the full capabilities of the controls.

- Proven Reliability: With a track record of success in various industries, Control Chief’s wireless remote controls are trusted by companies worldwide to avoid unexpected downtime.

In today’s competitive industrial landscape, minimizing unplanned downtime is crucial for maintaining productivity and profitability. Every minute you’re not working is a minute that your competitors ARE working. Control Chief’s wireless remote controls provide a powerful solution to minimize work stoppages, which often come with catastrophic financial losses.

By investing in advanced wireless technology, companies can ensure their operations are optimized for success.

For more information, contact Control Chief sales manager Mark Childs or industrial sales consultant Nicole Alter here. Or call (814) 362-6811. Let’s work together to create a more productive work environment in your industry.

Views: 31